FILTRATION MACHINE- Continuous Filters

In

beneficiation plant, filtration machine can be divided into three modes:

continuous, batch and semicontinuous, and clarifying. Each of these modes can

be further subdivided. The discussion that follows is limited to those units

with significant application in mineral and coal processing.

Continuous Filters

Continuous

filters may be divided into those forming their filter cake against gravity and

those forming their filter cake with gravity.

Filters

Forming Cake Against Gravity. Disk and drum filters all form cake against gravity. The latter can be

further divided into scraper discharge, roller discharge, and continuous-belt

drum filters.

A

disk-type filter contains a series of individual disks mounted on a center barrel.

The barrel is held in trunion bearings mounted on either end of the filter

tank. The disks are partially submerged in the feed slurry to a standard

apparent submergence of about 35%. A higher submergence would require stuffing

boxes around the center barrel, a procedure that is very seldom used because of

the large diameter required of the stuffing boxes and the abrasiveness of the

solids generally processed.

Each disk

is divided into 8 to 12 pie-shaped disk sectors depending on the disk diameter.

A filter bag covers the sectors’ filtration area, and filtration occurs on both

sides of the disk sector. Each sector is held in by radial rods between sectors

that attach to the center barrel. A bag clamp that covers half of the end of

the adjacent sectors holds the sector in place after a nut is applied to the

end of the radial rod. At the narrow end of the sector, a pipe outlet connects

to the ferrule socket with proper gasketing, and it delivers filtrate and air

pulled through the cake to a port within the center barrel. The number of port

filtrate channel equals the number of sectors per disk. The filter bag is tied

around the filtrate outlet of the sector and nailed, stapled, or clamped to the

top of the sector. Channels within the center barrel end in a wear plate (which

attaches to the pipe plate) with the port openings in a circle. A stationary

face of the filter valve is held to the rotating wear plate by a centering pin.

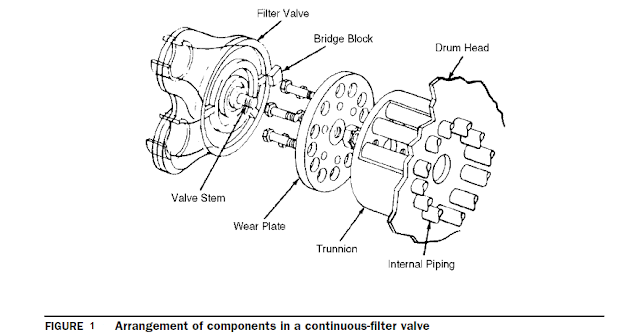

Figure 1 is an exploded view of a typical valve. The stationary valve portion has

a bridge ring so that bridge blocks can be inserted to separate the various

phases of the filter cycle. For example, a bridge block whose width covers the

port width would be placed before and after that portion of the filter cycle

when compressed air is blown through the ports, sector, and filter media to

dislodge the cake. A scraper blade also assists in the cake discharge by riding

on either side of the disk. By pivoting the blade in the rear of the sector and

hanging the front end so that the shoe rides on the periphery of either side of

the disk, the blade can be automatically separated from the face of the sector

by 1/4–3/8 in. and thereby conform to any vertical variation in each

disk.

The exit

from the stationary filter valve face (normally one large or two smaller exits)

connects to a cylindrical receiver. Here the liquid filtrate separates from the

gas pulled through the cake, and the overhead line connects to the vacuum pump.

Thus the pressure differential of the vacuum pump provides the driving force

for filtration. The filtrate is either pumped from the receiver or discharged

from a vertical barometric leg, which is usually at least 5 ft higher than the

maximum vacuum that can be applied (measured in feet of water).

The cake

is discharged by a blow-back of compressed air through the valve, port, sector,

and filter media. A steady low-pressure blow of 3–5 psig, which continues until the

trailing edge of the sector passes the scraper blade, is commonly used. Higher

pressure blows of 10–30 psig use a solenoid valve triggered by a cam rider on the trunion. A

full blow for only a very few seconds tends to shock the cake from the

filtering surface. In this way, the filter cloth is not inflated when it passes

the scraper blade.

The cake

is discharged by a blow-back of compressed air through the valve, port, sector,

and filter media. A steady low-pressure blow of 3–5 psig, which continues until the

trailing edge of the sector passes the scraper blade, is commonly used. Higher

pressure blows of 10–30 psig use a solenoid valve triggered by a cam rider on the trunion. A

full blow for only a very few seconds tends to shock the cake from the

filtering surface. In this way, the filter

cloth is not inflated when it passes the scraper blade.

Because

the disk is applied to high-permeability filter cakes, the filtration rate is

generally high 25–700 lb of dry solids/h/ft2 of filtration

area. Therefore, particles are generally coarser than normal and must be

agitated to be kept in suspension. At the base of the filter tank, a shaft with

paddles between each disk and on either end maintains the solids in suspension.

The shaft has outboard bearings and drive, and it usually runs between 60–120 rpm.

The cake

discharges into chutes between each disk and on each end to a belt conveyor on

the lower floor.

The drum

filter consists of a cylinder with peripheral sections parallel to the central

axis. Each section is connected by tubing to the pipe plate, as in the disk

filter, and a wear plate matches the tube diameters and location. A filter

disk, normally of plastic grids of polyethylene or polypropylene, is contained

between the wings of the leading and trailing division strips. The filter cloth

is caulked into each division strip so that each section can be isolated from

the adjacent ones by appropriate bridge blocks in the valve. Either a caulking

groove or a flat strip is applied on both drum ends for sealing this portion of

the filter cloth.

Another

method of applying the filter cloth to the drum is by wire winding. In this

method a caulking rope or elastomer is inserted in each division strip so that

the edge protrudes through the caulking grove. Thus by wire winding the cloth

over these seals, the section can be isolated from adjacent ones as required

during each revolution. Wire winding is normally spaced at 1/2–2-in. intervals, and stainless-steel wire is most commonly used. In both

systems, the edges of either drum end are sealed with wire winding or plastic

strapping.

Tubing

connections to the leading and trailing edges of a section are normally joined

to a single manifold pipe that in turn connects to the wear plate. The size and

number of leading and trailing edge connections should cause the minimum

hydraulic restrictions. Pressure drop at maximum flow should not exceed 2 in.

of mercury between the filter media and the suction side of the vacuum pump. If

high temperatures and vacuum levels cause the filtrate to flash, resulting in

two-phase flow, the pressure drop is even more important in designing the

filter drainage network.

The type

of drum filter is determined by the way in which cake is discharged. The most

common types in the mineral industry are scraper discharge, roller discharge,

and continuous belt.

In a

scraper discharge drum filter (Figure 2), the cake is removed by a scraper

blade, which is assisted by a blow-back of pressurized air. The scraper blade

should not contact the filter media during blow-back, so a 1/4-in. separation

is usually required. Scraper filters are probably the most commonly used in

continuous service.

The

second type, a roller discharge drum filter, contains a small-diameter roll

that moves in a direction opposite to that of the drum. Because the roll’s

peripheral speed is normally slightly faster than the drum’s, a pool of cake

forms between the drum and the roll. The surface of the drum is covered at

discharge so that very thin cakes (1/32–1/16 in.) can be

discharged completely. Probably the most common roll is fabricated of a plain

steel or an alloy steel. The cake sticks best to itself, and therefore, a

“heel” about 1 in. deep is plastered onto the roll. The cake stuck to the roll

is then cut off by a knife at 90° or 180° from this point. Figure 3 is a

schematic of a roller discharge system for the filtration of kaolin clay that

has been leached with sulfuric acid to remove iron. The roll has a heel of

clay, and the drum rotates as fast as once every 20 rpm.

This

system has also been used to treat alumina red mud (bauxite residue after

leaching in caustic solution) and extremely fine tailings. It can discharge

very thin cakes at high drum speeds, and colloids compose 80%–100% of the total suspended solids in

the cakes.

The third

type of drum filter, the continuous-belt drum filter, discharges cake by

continuously removing the cloth (Figure 4). The cloth is carried over a

small-diameter discharge roll where the large difference in the radius of

curvature tends to release the cake from the cloth. A deflector blade completes

the discharge. To maintain a clean and unblinded cloth, spray nozzles can then

be used to wash the cloth on one or both sides. This wash water is collected

separately, and the cloth travels around the wash roll and then around a return

roll to be placed back on the drum to begin the cycle again.

A

continuous filter can discharge cakes as thin as 1/16–1/8 in., a

thickness that maximizes the filtration rate. Furthermore, maintaining the

cloth free of blinding again increases filtration rate, which is normally 20%–50% higher than that of a scraper

discharge filter. This difference persists when it is measured over the life of

the filter cloth.

Because

of the dimensional instability of textiles, continuous-belt filters must always

control four aspects of filter media alignment at all times: the cloth must be

centered across the face of the drum; one edge must not lead or trail the

other; the center must not lead or trail the edges; and the cloth must be free

of wrinkles.

This type

of filter finds wide application where solids that cause blinding are

encountered or where compounds can chemically precipitate within the filter

cloth. Its higher price per unit area is more than offset by its high capacity

per unit area.

Filtration

area is measured by the surface area of the drum or π (diameter × length).

Drums are usually 4–12 ft in diameter, at 2-ft increments. A 14-ft–diameter drum would have to be shipped

separately from the filter tank to clear bridges and tunnels and generally

represents the largest size that can be shipped.

Face

widths of 40 ft are the largest used in scraper discharge and roller discharge

drums; widths of 20–24 ft are about the maximum in continuous-belt drum filters.

Another

type of drum filter, the continuous drum precoat filter, is used to produce

clear liquids. The machine employs a drum similar to the ones previously

described, but a microadvance knife cuts off a very thin layer of the precoat

bed on each revolution, normally 0.0015–0.006 in. per revolution. The precoat

bed consists of diatomaceous earth (fossil remains of diatoms), expanded

perlite, or other precoat material that will filter out the usually very fine

particles that must be removed from the liquid.

The

precoat bed is applied by filtering it on the filter media to a thickness of 3–6 in., depending on the application and

the filter design. The feed is then applied to the tank and the precoat knife

cut and the filter cycle time adjusted to the optimum value for the feed. The

normal precoat cut will be about 0.003 in. per revolution. The solids filtered

out must be cut off during each revolution; otherwise, the bed may blind. If

penetration is too great, it will be more economical to use a “tighter” grade

of precoat material.

After the

precoat thickness is shaved down to approximately 1/4 in., the knife is retracted, the bed is

sliced off, and the process is repeated.

Feeds for

this type of filter are normally less than 5 wt% suspended solids, and, in most

cases, less than 2 wt% suspended solids. The unit finds its widest application

in such areas as hydrometallurgy, where a clear filtrate must be produced.

Thus, it would be used on gravitational thickener overflows or continuous

filter filtrates. It is the only continuous filter that produces a clear

filtrate.

Filters

Forming a Cake with Gravity. The scroll discharge horizontal table filter and the continuous

horizontal

belt filter are filters that form a cake with gravity. The former consists of a

circular disk with filter media on the top side. The table is divided into

pie-shaped sections, and a gridwork supports the filter media in each section.

The filtration area is calculated as the annular area between the outside and

inside diameters.

At the

discharge point a scroll cuts off the cake and drops it over the side to a

conveyor belt or other type of transfer unit. At the inner radius of the

section, the filtrate pipe connects to the wear plate of the filter valve. The

valve is mounted underneath the filter in the center and the outlets point

downward. Otherwise, the valve is similar to a drum and disk filter valve.

Because

of the scroll discharge, a heel of cake must be left on the filter because

otherwise the filter media would wear rapidly. Normally, the heel is 1/2–3/4 in. thick. The cake can be reoriented by blowing

back with

compressed air during the initial portion of the feed phase of the filter cycle

to retard blinding.

The

filter cake can also be washed to recover soluble constituents of interest.

Although the drum filter can be washed only by a single stage, a countercurrent

wash can be employed on this unit. Thus the wash fluid is applied first to the

last wash, and this filtrate is used as wash for the preceding stage. Two

stages usually suffice, but three have been used.

This type

of filter has been used to treat granular solids with a high cake permeability,

such as certain crystalline solids, particularly coarser ones whose solids

should be washed to remove impurities or to recover brines or dissolved

valuable salts. Sand or other granular solids of 20–100 mesh size are also dewatered on

this type of machine because high solids capacities and low moistures can be

achieved.

The

horizontal belt filter was developed to permit washing of the cloth and thus to

prevent blinding similar to that common in the continuous-belt drum filter. At

the same time, it is possible to use any number of countercurrent washes on the

individual machine as long as they are incorporated into the design.

Figure 5

is a schematic of a continuous horizontal belt filter that illustrates major

construction features. Two large-diameter major pulleys are employed and a

special grooved endless elastomer belt rides over the pulleys. The head pulley

(cake discharge end) is driven and normally the molded belt has a full-length

rib that is accommodated by a circumferential slot in each of the

rubber-covered pulleys. The drainage grooves, which are perpendicular to the

direction of motion of the elastomer belt, are such that the two adjacent

grooves drain to the same circular hole. The hole is drilled through the

elastomer belt and the center line of the rib (more than one drainage hole

across the width may be used, depending on the width of the belt and the

required hydraulics). The belt must incorporate enough plies of fabric to give

it sufficient strength in tension. The belt also employs side flaps or flanges

that contain the feed slurry and wash fluids. Metal deckle sides may be used to

contain feed or wash water, and hoods may be used to contain steam or hot gases

that might be applied for maximum dewatering.

The

filter media is made of plastic material such as polyethylene, polypropylene,

nylon, or polyvinyl chloride. It rides on top of the elastomer belt and is held

in place by the pressure differential across the cake and the filter cloth. The

media is separated from the rubber belt after the vacuum has been terminated,

and cake is discharged over a small-diameter roll. The roll’s small radius of

curvature at discharge helps separate cake from the filter cloth. The cloth is

then washed to prevent blinding, in a manner similar to that used for the

continuous-belt drum filter, and returned underneath the filter to the head

pulley for a repeat of the cycle.

The cloth

is kept in alignment by control systems such as those used on the

continuous-belt drum filter. In addition, a take-up system for the cloth must

be employed during the return of the cloth underneath the filter to take care

of any stretching or shrinking. The rubber belt is maintained in alignment by

the

individual takeups on the tail pulley.

The

rubber belt rides over the vacuum box (or boxes, depending on width or

hydraulic requirements) and a support table. The vacuum box serves as a “valve”

on the filter because a seal must be made between the stationary face of the

vacuum box and the moving face of the elastomer belt. Because of the pressure

across these faces, low-friction surfaces on the vacuum box, such as

fluorocarbon plastics, must be used. These faces can be lubricated by water or

a clear filtrate delivered through pressure lines into the faces. In the case

of heavy cakes or long filters, it is desirable to use a low-pressure fan blowing

into a plenum with entrance ports into the support table under the belt. Dividers

in the vacuum box are used to separate the various filtrates or washes as

desired. If different vacuum levels are employed within the cycle, the dividers

must ride against the belt for a width of one diameter of a drainage hole. The

gas and liquid filtrate are carried by pipes to the appropriate receiver where

the filtrate is separated from the gas. Flexible connectors allow the vacuum

box to be dropped for maintenance. Where scaling occurs, such as in phosphoric

acid manufacture, the vacuum box can be dropped by a gear motor or hand crank

to expose the box for easier descaling. The overhead of the receiver passes to

the vacuum pump to supply the driving force for filtration.

Wash

boxes are normally used to keep spray nozzles from plugging; spray headers may

also be used, particularly in single-stage washing or the last stage of

countercurrent washing. As many as five stages of countercurrent washing have

been employed to minimize the consumption of wash fluid. Major advantages of

this filter are

_ It can be employed with as many countercurrent wash stages as desired at a

high wash efficiency.

_ Cloth-washing systems eliminate cloth blinding without diluting the feed.

_ Coarse, fast-settling solids can be filtered because the cake forms with

gravity.

_ Very high belt speeds of 200 ft/min (61 m/min) or more can be used to

yield very high capacities per unit area.

_ The rectangular structure of the filter and its basic concept use floor

space efficiently, and all auxiliaries can be installed on the same floor as

the filter.

A

disadvantage is a higher price per unit area because of the rubber covering and

special elastomer belts that must be employed. However, capital costs should be

viewed on bases such as cost per unit of production or improved product

quality.

评论

发表评论