Coolers and heat recovery

In mineral processing plant, the temperatures of discharged products from thermal

processing are high. In order to lower that temperature, or to recover some

heat, or both, coolers are

used. Most of

the coolers are inversely working dryers, however, with a higher capacity per

installed unit.

Normally there

are three basic designs:

• Air Swept Coolers built similar as a counter flow direct heat

rotary dryer, where hot gasses are replaced with ambient air

• Water cooled shell coolers where the drum shell is cooled with water or

is submerged in a pool of water.

• Water tube coolers having the same design as a steam tube dryer,

where the steam is replaced with cool water

Coolers of fluid bed type

The principles

of fluid bed can be used also for cooling purposes. In this case the

fluid bed is

cooled by internal water pipes.

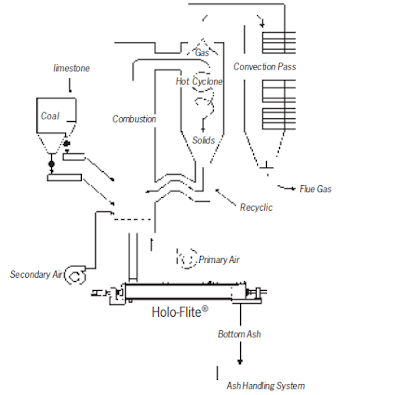

Ash Cooling

Circulating

Fluidized Bed Boiler

Coolers and heat recovery

Thermal

processing is a question of limiting the energy input for each part of the operation.

This is the strongest argument (together with environmental issues) in a competitive

situation for systems selection. The system with the best heat balance has

probably also the best heat recovery system utilizing the energy released from

cooling.

sinonine can also provide sand washing plant epc.

sinonine can also provide sand washing plant epc.

评论

发表评论