FILTRATION MACHINE- Batch and Semicontinuous Filters

In

beneficiation plant, Continuous filters tend to be more widely used in the

mineral and coal processing field, particularly where large tonnages are

involved. This preference reflects the lower capacities of batch or

semicontinuous units and the increased labor requirements, both of which result

in higher operating costs. However, at low-tonnage plants and under special

conditions, these filters can have distinct advantages. Also, where pressure

drops must be used that are higher than those obtained by continuous vacuum

filters (because of the low cake permeability), the pressure filter may be

applicable. For instance, tailings may be filtered to recover water or to

dewater them to a high enough solids concentration to allow land disposal. The

mineral and coal processing industry use batch and semicontinuous filters of

four types: plate and frame filters, recessed plate filters, vertical disk

pressure filters with or without sluice discharge, and automatic discharge

plate and frame-type filters. All four employ pressure filtration.

Plate

and Frame Filter.

The plate

and frame filter uses a plate that has a grooved or other type of drainage

system supporting the filter cloth. Both sides of the plate have grooved

patterns so that filtration occurs on either side. The frames will contain the

feed and filter cake and seal against the plate. Usually there are connecting

ports through the four corners of both plates and frames so that either feed or

filtrates can be accommodated. The feed may enter through one or more of the

corners where the ducts are accommodated into the frame interior but not into

the plate. The plates contain ducts in other corners for conducting the

filtrate. The filter cloths are draped over the plates and holes of the ports

in the corners are matched. A seal is made by the filter cloth between the

plates and the frames, although slurry can leak if the cloth is wrinkled or if

a piece of cake sticks between the plate and the frame. This possibility can

usually be prevented by using a gasketed plate.

Figure 1

shows a typical plate and frame unit and also shows the hydraulic closing

system. One head is stationary and the other can be moved by a double-acting

hydraulic cylinder. Thus, relatively high hydraulic pressures are employed to

close the press so that normal operating pressures up to 125 to 250 psig can be

obtained.

Also

shown in Figure 1 is a shifter mechanism, which discharges cake by mechanical

movement of the plates and frames. An operator should make sure that the cake

discharges and that pieces do not hang up on the sealing surfaces; such pieces

could cause a very leaky joint or even break the plate or frame on closure. The

operator usually has a wooden paddle to take care of these instances, and as

soon as the paddle breaks a photocell path, the mechanical operation stops.

After the operator has

corrected

the situation, he restarts operation by pressing a button that moves with him.

In

smaller filters, a hand crank can be used in place of the hydraulic cylinder at

a lower cost. The plates and frames can also be moved manually, but doing so

usually requires two operators.

The

filter cakes can be washed by using the feed lines for introducing wash fluid.

Because the cake is being washed from a point source, the fluid tends to follow

shorter paths to the filtrate side and the wash is not as effective. The wash

is more efficient if every other plate is a washing plate. The wash fluid

enters this plate behind the filter media on both sides and passes through the

cloth to the opposite filter media and plate. Thus, a more consistent short

flow path is obtained across the cake area.

Many

different filter media can be used, ranging from canvas to synthetic woven

fibers to nonwoven synthetics. To obtain very clear filtrates, special papers

are also employed either as the sole media or over a backing cloth.

Plates

and frames were formerly made of wood, cast iron or other metals, and

rubber-covered steel. Currently, thermoplastics, such as polyethylene and

polypropylene, have largely supplanted the earlier materials. These newer

materials not only reduce costs but also greatly reduce weight. They are used

at the normal operating pressures of 125–250 psig.

Frames

generally are 1–2 in. deep depending on the specific cake permeability. Plates are usually

square and are 12–48 in. on each side. The frame depth should be carefully determined,

because the plate and frame filter work best when the frame is entirely full of

cake at the end of the filtration cycle. If it is not, the frame may contain

too much fluid and produce a high-moisture cake. In addition, a thicker final

cake may result in an appreciably lower filtration rate in terms of pounds of

dry solids per hour from the press.

The feed

pump may be either a centrifugal pump or a positive displacement pump,

depending on the type of solids in the feed and the filtration pressures. If

final filtration pressures permit and the solids or flocculi are not injured by

the pump, single-stage or multistage centrifugal pumps can be used.

At higher

pressures or where the solids or flocculi are fragile, the positive

displacement type pump is used. Controls should be used to prevent excessive

pressures that could injure the filter

press.

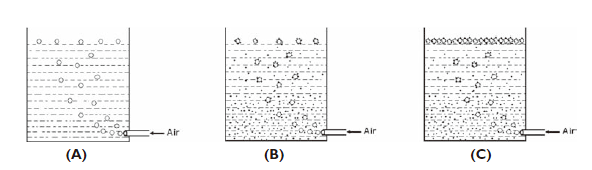

A common

auxiliary is an air or gas compressor that blows the cake at the end of the

filtration cycle for further dewatering. Where tailings or refuse are filtered,

the solids must be flocculated because they contain large amounts of colloids.

Flocculation requires a mix tank preceding the feed pump and complementary

equipment to prepare and dilute flocculant. Bench-scale investigations will be

required to determine the type and dosage of flocculant, the mixing power, and

the duration of mixing. Because flocculi generally deteriorate with time, the

length of time that flocculated pulp is stored will be important, as the

filtration rate is not constant at all times with batch equipment.

Recessed

Plate Pressure Filter.

A similar

type of press but one that eliminates the frame is the recessed plate pressure

filter. The plate has a center feed and all feed enters through this port. The

filter cloth must be sewn or a fixture employed to seal the cloth on both sides

of the plate at the feed port. In addition, the plate is recessed to allow for

cake buildup. This recess is usually 1/2–l in. deep, yielding a cake thickness

of 1–2 in. Filtrate is collected at any one or more of the four corners;

filtrate ports are cast in the plates as with the plate and frame filter. Cake

washing, if necessary, is best practiced by using every other plate as a

washing plate with wash fluid entering at the top behind the filter media on

both sides of the plate. The wash fluid passes more evenly through the cake to

the opposite plate, where the filtrate is collected at the bottom corners.

The usual

plate sizes vary from 12-in. square to as much as 6 × 9 ft. As many as 175

plates may be incorporated into one press; the maximum plate size yields a

filtration area of 18,585 ft2. Plates are available

in a wide range of materials but molded plastic dominates, particularly in the

large sizes. Auxiliary equipment is similar to that discussed under plate and

frame filters. However, with the larger units, the feed ports may be doubled to

achieve the proper hydraulics and feed distribution. In addition, the press is

constructed so that the feed ports may be blown out by compressed air through the

follower end (a movable closure head); the compressed air removes the higher

moisture core and also further dewaters the cake. Mechanical plate shifters are

also employed on recessed plate filters. Because of the large size of these

filters, large plate shifters that move as many as 12 plates at a time for cake

discharge can be used. This device reduces the time for cake discharge to a very

few minutes and increases the overall filtration rate.

Figure 2

is a picture of a typical recessed plate with a gasketed construction that

eliminates leakage and reduces filter-media wear.

评论

发表评论