Mineral processing unit operation and examples

UNIT OPERATIONS

In mineralprocessing plant, Numerous

steps, called unit operations, are involved in achieving the goal of extracting

minerals and metals from ores in their purest possible form. These steps include

Size reduction. The process of crushing and grinding ores is known as

comminution. The purpose

of the

comminution process is threefold: (1) to liberate valuable minerals from the

ore

matrix,

(2) to increase surface area for high reactivity, and (3) to facilitate the

transport of ore

particles

between unit operations.

Size separation. Crushed and ground products generally require

classification by particle size. Sizing can be accomplished by using

classifiers, screens, or water elutriators. Screens are used for coarse

particulate sizing; cyclones are used with fine particulates.

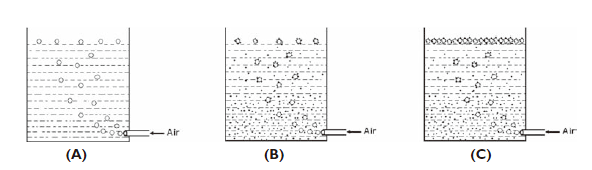

Concentration. Physicochemical properties of minerals and other solids

are used in concentration operations. Froth flotation, gravity concentration,

and magnetic and electrostatic concentration are used extensively in the

industry.

— Froth flotation. The surface properties of minerals

(composition and electrical charge) are used in combination with collectors,

which are heterogeneous compounds containing a polar component and a nonpolar

component for selective separations of minerals. The nonpolar hydrocarbon chain

provides hydrophobicity to the mineral after adsorption of the polar portion of

the collector on the surface.

— Gravity concentration. Differences in the density of minerals

are used to effect separations of one mineral from another. Equipment available

includes jigs, shaking tables, and spirals. Heavy medium is also used to

facilitate separation of heavy minerals from light minerals.

— Magnetic and electrostatic

concentration. Differences

in magnetic susceptibility and electrical conductivity of minerals are utilized

in processing operations when applicable.

Dewatering. Most mineral processing operations are conducted in the

presence of water. Solids must be separated from water for metal production.

This is accomplished with thickeners and filters.

Aqueous dissolution. Many metals are recovered from ores by dissolving the

desired metal(s)—in a process termed leaching—with various lixiviants in the presence of oxygen. Following leaching, the

dissolved metals can be concentrated by carbon adsorption, ion exchange, or

solvent extraction. Purified and concentrated metals may be recovered from

solution with a number of reduction techniques, including cementation and

electrowinning.

EXAMPLES OF MINERAL PROCESSING

OPERATIONS

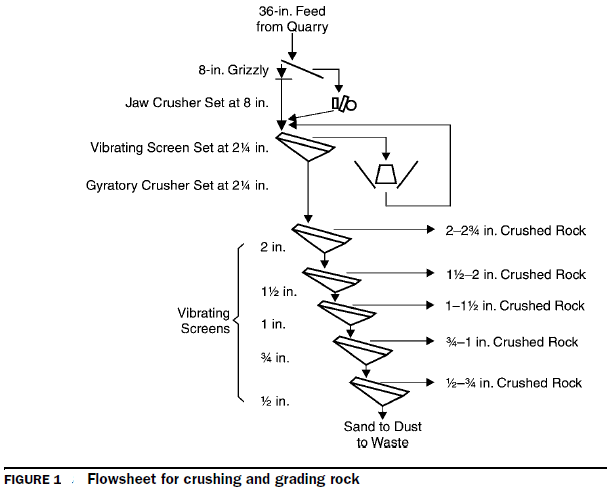

Figure 1

shows a typical flowsheet for crushing and sizing rock in a quarrying

operation. Run-of-mine ore can be present as lumps as large as 1.5 m (5 ft) in

diameter. In this figure’s example, 91.4-cm (3-ft) lumps of rock are fed to a

crusher that reduces the material to 20.3 cm (8 in.) or less in diameter. After

screening to remove rock that is less than 57.2 mm (21/4 in.) in size, rock between the sizes of

57.2 mm (21/4 in.) and 20.3 cm (8 in.) is further reduced in size by a gyratory crusher.

The product from this step is then classified by screening to the desired

product for sale.

Figure 2

shows an integrated circuit demonstrating crushing, grinding, size separation,

and gravity concentration of a tin ore. Initial size separation is effected

with a grizzly set at 11/2-in. Oversize material is fed to a jaw crusher set at 11/2-in., and the

crushed product is, then, further reduced in size to 20 mesh by ball milling.

The –20-mesh material is classified by hydrocyclones set at 150 mesh, and the –150-mesh material is sent to shaking

tables to concentrate the heavy tin mineral, cassiterite. The middlings in this

process receive additional treatment. The concentrate from this operation is

reground and sized at 200 mesh. Two-stage vanning is used to produce a fine tin

concentrate.

The

flowsheet describing the flotation processing of a copper ore containing

chalcopyrite and molybdenite is shown in Figure 3. After grinding and

classification, pulp is fed to rougher flotation. The rougher tailings are

thickened and sent to a tailings dam. The rougher concentrate is classified, and

the oversize is reground. Cyclone overflow is fed to cleaner flotation, and the

cleaner concentrate is recleaned. Cleaner tailings are recycled back to rougher

flotation, and the recleaner concentrate is thickened and sent to the

molybdenum recovery plant for further processing. In this operation, the feed

contains 0.32% Cu and 0.03% Mo. Rougher concentrate, cleaner concentrate, and

recleaner concentrate contain 7%–9% Cu, 18% Cu, and 25% Cu, respectively. Recleaner

concentrate also contains 2%–3% Mo.

Figure 4

depicts a flowsheet for processing free-milling oxidized gold ore. The kinetics

of gold leaching is slow, and gold ores are frequently ground to less than

about 75 μm before leaching. Even then, one day is usually required in the

leaching step. In this process, run-of-mine ore is crushed and ground. The ball mill discharge in subjected to gravity concentration to recover the larger

particles of free gold. The tailings from this operation are thickened, and the

underflow from the thickeners is then subjected to cyanide leaching. In some

instances, ores may contain oxygen-consuming minerals, such as pyrrhotite and

marcasite, and a preaeration step may be conducted ahead of cyanide leaching.

Heap

leaching has revolutionized the gold mining industry. Low-grade oxidized ores

containing approximately 0.03 oz gold per short ton of ore can be processed

with this technology, whereas they could not be processed by the higher cost

grinding/agitation leaching (milling) process. Figure 5 presents a simplified

flowsheet of heap leaching. As the figure shows, run-of-mine ore may or may not

be crushed. If crushing is done, the ore is generally crushed to <2 in. in

diameter.

sinonine can also provide sand washing plant epc.

Sinonine technology team

评论

发表评论