Mobile beneficiation plant system

In mineral processing plant,modern quarrying, mining, tunnelling

and recycling operations the use of mobile process systems is increasing

dramatically.

Particularly at

rock front operations the technique of “moving the process equipment closer to

the front end” using mobile crushing and screening units in many cases gives

remarkable cost savings.

These mobile

units represent one or more complete machine functions including materials

handling, power supply etc. Advanced process control secures the “intelligence”

of the system.

Mobile Crushing and Conveying System

Key arguments

for mobile equipment vs stationary equipment and damp truck

haulage are:

•

Less hauling –

less costs

•

Less front road maintenance

•

Less exhaust gas and dust emissions

•

Improved working safety

•

Improved flexibility

Primary Jaw Crusher + Grizzly

Primary

Impact Crusher + Grizzly

A pre-assembled Ore Concentrating

Plant

Typical

units at approx. 10 t/h capacity

1.Crushing unit

Jaw- and cone

crusher in closed circuit with a double deck screen Weight app. 19 ton,

transportation measures W= 2,6m, H= 4.2m

2. Grinding unit

Grinding mill

(ball mill or rod mill ), pump and hydrocyclone Weight app. 25 ton, transportation

measures W= 3,0m, H= 3,8m

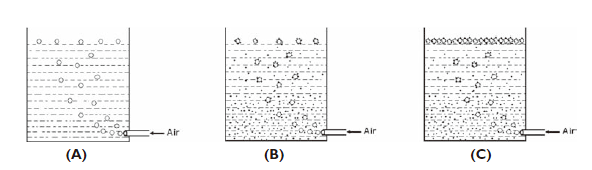

Rougher,

scavenger and cleaner cells together with conditioners, reagent feeding systems

and air blower. Weight app.14ton, transportation measures W= 2,5m, H= 4.2m Units

for leaching and gravity separation (dense media, tables and spirals) also

available

4.Dewatering unit

Compact sedimentation

(lamella unit) and vacuum filter with auxiliary equipments

5. Power unit

Diesel driven

generator including connection terminal Transportation measures W= 2,5m, H=

3.8m

sinonine can also provide sand washing plant epc.

sinonine can also provide sand washing plant epc.

评论

发表评论