Beneficiation Processing of Iron ore

Beneficiation

Processing of Iron ore

Sinonine deeply know that most prominent

ore found in world are mainly hematite and magnetite. Among these, hematite is

considered to be most important. Iron ore is used in production of pig iron

which is further used in production of steel other uses of iron ore are like

industrial finishes, polishing compounds and sponge iron industries. Iron ore

belongs to Precambrian stage and its deposit is present in massive, laminated,

friable and also in powdery form.

Hematite

Hematite is most important iron ore

mineral main source for industries. Its composition is Iron Oxide and sometimes

slight amount of titanium. Its name comes from the Greek word for blood, haima,

because of its reddish colour. Crystals occurs in thin plates, as well as

bundles of small micaceous plates, and in thin splinters. Most commonly

massive, mammilary, botryoidal, reniform, oolitic, stalactitic, and radiating.

Scalenohedral and rhombohedral crystals occur, although infrequently, and

dendritic and rosette forms are also found. Hematite may also form as a

pseudomorph of other minerals, especially as octahedral crystals of Magnetite.

Striking features are reddish streak, hardness, crystal habits and Para

magnetism. It becomes strongly magnetic when heated. Its specific gravity is

4.9 to 5.3 and luster is metallic to dull. Hematite is weakly magnetic, but it

has a variety called magnetite which is found in many ore bodies in minute

quantities having magnetic properties closely related to those of magnetite.

The content of iron in the ore and physical characteristics vary from place to

place in different types of ores.

Magnetite

After hematite, magnetire is second most

abundant Iron bearing ore. Black magnetic oxide of iron crystallizing in the

isometric system with hardness of 5.5 to 6.5. Magnetite ore is of little value

in its raw state, but it offers considerable advantages in its concentrated

form. These include providing a viable iron-making commodity for premium

quality steel production. By comparison, magnetite ore typically has much lower

iron content when mined of between 25%

and 40% Fe and in this form is unsuitable for steel making. The main iron

mineral in magnetite ore is the ferrous iron oxide magnetite (Fe3O4). Magnetite

ore requires complex processing to separate magnetite minerals from other

minerals in the ore to produce an almost pure magnetite concentrate with an

iron content of between 68% Fe and 70% Fe that is highly sought after by steel

makers. It also occurs as a replacement product in sedimentary or metamorphic

rocks. It is found as placer deposits as ―black sand‖ in beach deposits and as banded layers in

metamorphic and igneous rocks.

Processing

of Iron ore

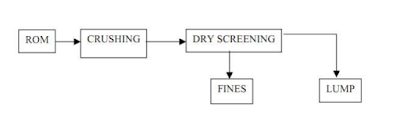

Iron processing depend mainly on the type

of ROM ore feed and optimum product. Dry screening into lumps and fines is

practised for high quality flaky ore and blue dust, because, if wet treatment

is used, a substantial part of good quality material is rejected in the form of

slimes. Another advantage of dry screening is dry screened fines also retain

ultra-fines particle may later be used in sintering. Ore types having gangue

material which strictly adhere to the useful metal surface are subjected to wet

screening -> classification or scrubbing -> wet screening ->

classification. Mineral processing plants at mines usually use dry screening

for direct ore mined from the face.

Part of plants use wet screening -

classification for ores that meet the cut off criteria. Scrubbers are being

used in some beneficiation plant for better recovery. Some mines have hydro

cyclones , screw classifiers for better beneficiation process . Log washers are

also being used to produce better and stable quality lumps of iron ore in some

mines. Various techniques and methods generally being used in iron ore processing

are schematically shown in the figures below.

Fig 1 Dry

screening process

Fig 2 Wet

screening classification

Fig 3

Scrubbing wet screening classification

Fig 4

Washing and gravity separation process

Slimes

of Iron ore

For improving quality and to reduce cost

of production iron ore industries are demanding high grade raw minerals.

However, the ore being a non-renewable natural resource, the reserve of good

quality ore is depleting. Marginal to sub-marginal ore should be used to meet

the present as well as future requirements and avoid environment related

problems. The circumspect utilization of Iron ore can conserve high grade

mineral resource. So today there is need of sustainable development in iron ore

mining that is need of present without compromising the need of future

generation. So it becomes vital to develop some technique for beneficiation of

unutilized low grade ore and ultra-fine material i.e. slime. Washing plant data

implies that generation of slime comprise of 30-35% of the total ore mined.

Because of lack of technology and its complex nature, a significant quantity of

slime remains unused. These slimes are dumped which causes environmental

hazards. If pellets are produced directly from such fines, they become high in

alumina which is undesirable in Blast furnace as high alumina content will

adversely affect the pellet properties, typically measured by Reduction

Degradation Index (DRI) and Reducibility Index (RI). A drop in alumina content

can improve these properties and also reduce the coke consumption in Blast

furnace. Tailings contain harmful material like iron sulphide which is primary

source for acid mine drainage. Sedimentation test show that the tailings and

the area required for tailing pond is around 3155 m 2 in comparison to 10,000

m2 obtained from the use of an empirical equation. It is

very difficult to evaluate the characteristics of these slimes where

most of the particles are below 50 microns. Base on the fact that iron ore

production wills more than double and rise to at least 300 million tonnes soon,

finding suitable methods of safe disposal/utilization of slimes is indeed

urgent. If we look at the present quantity of the iron ore slimes that is being

generated annually, amalgamation of quantity of slimes, over the years the fact

that slimes are available in ground form and assaying that is reasonably high

%Fe, it is natural that if beneficiated in a proper way, these slimes can be

considered a national resource rather than a waste. The alumina content of the slimes,

if brought to less than 2% Al2O3 in the beneficiated product will

---Lead to better utilization of national

resources.

---Achieve more mine output (enhanced

production) with not much additional costs.

---Reduce environmental issues associated

with storage and disposal of slimes.

---Result in higher blast furnace and

sinter plant productivity.

In view of the above facts proper

technology shall be adopted for processing of slimes to recover iron ore values

from them, this will be a step forward for conservation of mineral in national

interest. As particle size in slime is finer (<.15mm) so it will be easy to

beneficiate

the slime without the use of any

combination process.

In last twenty years importance is slowly

tilting towards slime beneficiation and in addition to the traditional methods

of processing, enhanced gravity separators (EGS) such as Falcon, Knelson

concentrator are also being experimented with to beneficiate the Slimes. Now aday’s

novel method of beneficing iron ore slime is used via magnetic and gravity

method ofseparation.

Two distinct mineral constituent of

Alumina iron ore slimes are gibbsite (hydrated aluminium oxides) and kaolinite.

Exact amount of alumina has not been quantified till date according to

liberation studies a significant portion of alumina is present in the liberated

form and so it is possible to separate them using physical methods. Slag

viscosity in blast furnace is increased due to high alumina content. This leads

to increase in metal loss in slag, increase in thermal requirement and thus

makes the Blast furnace operation more tough. To reduce alumina burden new

technologies are adopted by steel industries. Using pellets can reduce this

burden.

All around the world Iron ores are being

beneficiated,Several Methods such as

---Spiral

---Floatex density separators

---Jigs

---3 multi-gravity separator

---Low and high intensity magnetic

separator

---Conventional as well as column

flotation

---Selective dispersion

---Flocculation is all part of current

industrial practice.

评论

发表评论