Mineral magnetic separators

The machines used for magnetic separation are

called magnetic separators. The principle operation of a magnetic separator is:

When a stream of ore particles is continuously

passed through a field of magneticforce, the magnetic particles are attracted

towards the source of magnetic force while the non-magnetics travel unaffected.

Magnetic separation, in an industry, is achieved by

simultaneously applying a magnetic force on all particles of an ore which acts

on magnetic particles and a combination of forces which acts in a different

direction and affects both magnetic and nonmagnetic particles. The most

commonly applied nonmagnetic forces are gravitational, centrifugal, and fluid

drag. Other forces which usually enter in an incidental manner are frictional,

inertial and attractive or repulsive inter-particle forces.

These forces depend on both the nature of the feed

material and the character of the separator. The nature of the feed material

includes its size distribution, magnetic susceptibility and other physical and

chemical properties that may effects the various forces involved.

Magnets used in magnetic separators are of two

types; Permanent magnets and Electromagnets. Permanent magnets are magnetized steel

bars which retain magnetism indefinitely. Special-permanent magnet alloys

produce a magnetic field at a constant level indefinitely after initial

charging. The newer ceramic permanent magnets in the form of barium and

strontium ferrites, and rare-earth-cobalt permanent magnet alloys are also

being in use. Bars of soft wrought iron, soft steel or cast iron are magnetized

by electric currents through the insulated copper or aluminum wire windings

around the iron bars. These iron bars form electromagnets as long as the

current flows through the windings.

Magnetic separators, can be classified into two

groups based on their function:

1 Tramp

iron magnetic separators are those used to remove tramp iron and protect

the handling and processing equipment.

2 Concentrators

are those used to separate the bulk of magnetic materials from a stream

of ore. Magnetic separators that are used to remove small quantities of

deleterious magnetic material from a product (e.g. from china clay) are termed

as purifiers. The concentrators

that remove magnetic material from a product and return to the process are

termed as reclaimers (e.g.

separation of medium particles such as magnetite, ferrosilicon etc. in Heavy

Medium Separation process).

These magnetic separators are classified into dry

and wet separators which may further classified into low- and high-intensity

separators. Wet separators are generally used for the particles of below 0.5 cm

size.

1 Tramp iron magnetic separators

Iron coarser than 3 mm is usually called tramp

iron. Most commonly applied magnetic separators for removing tramp iron are

suspended magnets, magnetic pulleys, and grate magnets. Suspended magnets are

fixed position electromagnets of rectangular shape and installed over a

conveyor belt or head pulley (Figure1). Tramp iron attracted by the magnet is

periodically removed. Cross-belt models (Figure 1) are used when the continuous

removal of tramp iron is required. In a magnetic pulley, magnets are located

within the head pulley of a belt conveyor (Figure 5). The tramp iron is

attracted by the magnetic pulley and carried to distant place and discharged

when the material comes out of magnetic field while the required material is

discharged at the same place. Grate magnet consists of a series of magnetized

bars (Figure1) and is used to remove fine iron as well as tramp iron. Feed is

usually vertical through the grate. These magnets must be periodically cleaned.

Figure 1 Tramp iron magnetic separators

2 Concentrators

These magnetic separators are classified into dry

and wet separators which may further classified into low- and high-intensity

separators. Wet separators are generally used for the particles of below 0.5 cm

size.

2.1 Dry magnetic

separators

Drum separators are common low-intensity dry

magnetic separators. These are applied in concentration and purification where

magnetic particles to be removed are large in size and the magnetic

responsiveness of the magnetic particles is high. This operation of picking up

strongly magnetic particles at a coarser size is called cobbing operation. Drum separators consist of a rotating

non-magnetic drum containing either permanent or electromagnets. Magnetic

particles are attracted by the magnets, pinned to the drum, conveyed out of the

field and discharged while the nonmagnetic particles are discharged unaffected.

The magnetic drum is normally fed at the top vertical center, but, with

appropriate magnet positioning, it can be fed at any convenient point or even

front-fed or underfed (Figure1).

Drum separators are common low-intensity dry

magnetic separators. These are applied in concentration and purification where

magnetic particles to be removed are large in size and the magnetic

responsiveness of the magnetic particles is high. This operation of picking up

strongly magnetic particles at a coarser size is called cobbing operation. Drum separators consist of a rotating

non-magnetic drum containing either permanent or electromagnets. Magnetic

particles are attracted by the magnets, pinned to the drum, conveyed out of the

field and discharged while the nonmagnetic particles are discharged unaffected.

The magnetic drum is normally fed at the top vertical center, but, with

appropriate magnet positioning, it can be fed at any convenient point or even

front-fed or underfed (Figure2).

Figure2 Dry magnetic drum separators

Magnetic drum is also used for tramp iron removal.

Magnetic head pulley and grate magnet used for tramp iron removal are also used

as concentrators. Grate magnet is especially useful for purification of the

product when it contains small amounts of unwanted magnetic particles.

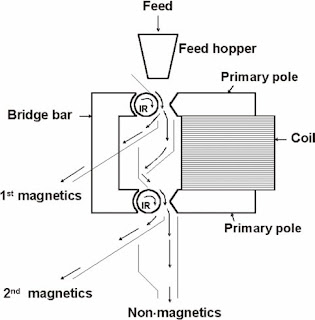

Induced roll separator and cross-belt separator are

the two high intensity dry magnetic separators. Induced roll separator (Figure3) consists of a horseshoe magnet

faced by an iron bridge bar or keeper and of two rolls, one opposite each pole.

The magnetic circuit is completely in iron except for the very small clearance

between the rolls and the bridge bar and for the gaps between the rolls and

primary poles of horseshoe magnet. The rolls consist of alternate laminae of

permeable and impermeable material with a serrated profile and produce the high

field intensity and gradient required. The field strengths of up to 2.27 T are

attainable in the gap between feed pole and roll. Non-magnetic particles are

thrown off the roll into the tailings compartment, whereas magnetics are

gripped, carried out of the influence of the field and discharged. The gap

between the feed pole and rotor is decreased from pole to pole successively to

separate weaker magnetic products.

Cross-belt separator consists

of two or more horseshoe electromagnets arranged with poles of opposite sign in

apposition, one electromagnet being below and the other above the feed belt.

The poles of the upper magnets are wedge-shaped while the lower poles are flat.

This concentrates the field and attracts the paramagnetic minerals toward the

wedge-shaped poles. Dry material is fed in a uniform layer on to the conveyor

belt and is carried between the poles. The cross-belt prevents the magnetic

particles from adhering to the poles and carries them out of the field. Disc separator is the modification of

the cross belt separator wherein discs revolve above a conveyor belt and are

magnetized by induction from powerful stationary electromagnets placed below

the belt. A disc separator permits a much smaller air gap and provides a

greater degree of selectivity in separating the minerals differing in their

magnetic susceptibility slightly.

Figure3 Induced

roll magnetic separator.

2.2 Wet magnetic

separators

Drum separators are most common low-intensity wet

magnetic separators. They consist of a rotating non-magnetic drum containing

three to six stationary magnets, either permanent or electromagnets, of

alternating polarity. Magnetic particles are lifted by the magnets and pinned

to the drum and are conveyed out of the field leaving the gangue particles.

Water is introduced into the machine to provide a current which keeps the pulp

in suspension. Three types of drum separators namely concurrent type, counter-rotation

type and counter-current type

(Figure 4) are in use. Concurrent type separators are used when clean

concentrate is required from relatively coarse material such as heavy medium

recovery systems. Counter-rotation type separators are used in the roughing

operation of larger tonnages. Counter-current type separators are designed for

finishing operation on relatively fine material.

Figure.4 Low-intensity

wet drum magnetic separators.

The Readings are wet high intensity magnetic

separators (WHIMS). The unit (Figure5) consists of a rotating carousel, which

has vertically inclined salient plates through which feed slurry is passed. As

the carousel rotates, it passes through fields of magnetic influence generated

by surrounding electromagnets, followed by fields of no magnetic influence. The

magnetic grains are initially held up in the plates while the non magnetic

grains are washed through into a launder below. When the plates are in the non

magnetic field the magnetic grains are washed off into a separate launder

below.

Figure 5 Wet high-intensity

magnetic separator

In order to attract and hold paramagnetic

particles, both high magnetic field and a high field gradient are required.

These high gradient magnetic separators (HGMS) produce field strength of about

2 T. In HGMS, the slurry is passed through a container where it is subjected to

a high-intensity, high gradient magnetic field. The container is packed with a capture matrix made of stainless steel

wool. In the presence of magnetic field, paramagnetic particles become

magnetized and are trapped in the matrix while the unaffected non-magnetic

particles pass through the container. When the matrix is loaded to its magnetic

capacity, the slurry feed is stopped and the electric power is cut off. The

matrix is then backwashed to remove magnetic particles. Afterwards, the feed

and the power are resumed and the entire process is repeated. In the continuous

separator, the capture matrix is a continuous, segmented metal belt. The slurry

is introduced while capture matrix passes through the magnetic section of the

separator. The magnetized particles are trapped in the capture matrix. The belt

then travels in to the washing section to wash magnetic particles trapped on

the belt. The cleaned belt section then returns for the entire process to be

repeated.

评论

发表评论