Mineral processing-Electrical separation

If an ore contains conducting as well as

non-conducting minerals/particles, electrostatic separation or high tension

separation can be employed. Theoretically, it is not necessary that one of two

minerals should be a good conductor and the other be a poor conductor, but the

difference in their conductivity will affect the separation.

The basis of any electrostatic separation is the

interaction between an external electric field and the electric charges

acquired by the various particles. Particles can be charged by:

1 Contacting dissimilar particles.

2 Conductive induction.

3 Ion bombardment.

In every separation, two or more charging

mechanisms occur.

In charging by contacting dissimilar particles,

particles placed on surface are made to repeatedly contact one another as well

as the surface; the surface will acquire electrons from one type of particles

and give electrons to another type so that two types of particles are charged

with opposite charges. When they are passed through an electrostatic separator

consisting of two conducting plates across which a high voltage is applied,

positively charged particles are attracted towards a negative plate and negatively

charged particles are attracted towards a positive plate. This mechanism is utilized

in free fall electrostatic separators. However, this is not the major mechanism

in any of the electrostatic separators.

In charging by conductive induction, the particles

are placed on a ground conductor in the presence of an electric field. Then the

particles will rapidly develop a surface charge by induction. Both conducting

and non-conducting particles will become polarized, but conducting particles

will have an equi-potential surface through its contact with the grounded

conductor. The non-conducting particle will remain polarized.

In charging by ion bombardment, corona discharge is

obtained by appropriate shaping of the electrodes. Corona discharge is an

electrical discharge which occurs when one of the two conducting surfaces (such

as electrodes) of differing voltages have a pointed shape. A highly

concentrated electric field, set up at the tip of the pointed

shape electrode, ionizes the air (or other gas)

around it. These ions charge the particles by bombardment when the mineral

particles are caused to pass within the corona. For the discharge to a large

diameter cylindrical surface, a fine wire parallel to the cylinder gives the

optimum corona discharge.

The attraction of particles carrying one kind of

charge (positive or negative) towards an electrode of the opposite charge is

known as lifting effect as

the particles are lifted towards the charged electrode. Mineral particles

having a tendency to become charged with a definite polarity may be separated

from each other by the use of lifting effect even though their conductivities

may be very similar. For example, quartz is readily negatively charged and can

be separated from other non-conductors by using an electrode carrying a

positive charge. However, pure electrostatic separation (pure lifting effect)

is relatively inefficient.

The other effect which makes the electrostatic

separation more effective is the pinning

effect. Here, non- conducting mineral particles, having received a

surface charge from the electrode, retain this charge and are pinned to

the earthed surface due to the attraction between the charged

non-conducting particle and the grounded surface.

ELECTROSTATIC SEPARATOR

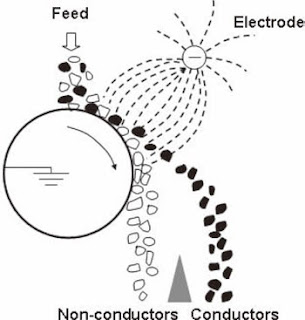

In

an electrostatic separator (Figure 1), a large single electrode produces a

strong electric field. When a particle is placed on the grounded rotor in the

region of the electrostatic field influence, the particle rapidly develops a

surface charge by induction. Whether the particle is a conductor or

non-conductor, it will be polarized. However, a conducting particle rapidly

becomes an equi-potential surface and has the same potential as the ground

rotor. Therefore it is attracted towards the electrode, drawn away from the

surface, and falls by gravity. The non-conducting particle continues to adhere

to the rotor until it falls by gravity.

Figure 1. Electrostatic separator

HIGH TENSION SEPARATOR

In a high tension separator (Figure 2), the mixture

of ore minerals is fed on to a grounded rotor into the field of a charged

ionizing electrode. The electrode assembly, consists of a lengthy fine wire

supported by a brass tube, is supplied with DC supply of negative polarity.

Then the ionization of air takes place which can be seen as corona discharge.

This gives a high surface charge to the poor conducting mineral particles.

These particles are attracted and pinned to the rotor. High conducting mineral particles

are not charged as the charge is dissipated through the particles to the earthed

rotor. Then they come under the influence of the electrostatic field of the

nonionizing electrode and are attracted (by the lifting effect) from the rotor

surface. They are discharged away from the rotor. The charge of poor conducting

mineral particles is slowly lost as the rotor rotates and the particles drop

from the rotor as middlings or non-conductor product according to the intensity

of the surface charge. Thus a combined effect of pinning and lifting is

experienced in high tension separators. These separators operate on feeds of 60

to 500 microns size.

Figure 2. High

tension separator

Since almost all minerals show some difference in

conductivity, electrostatic separation is the universal concentrating method.

It is widely used in beach sand beneficiation. The feed to electrostatic

separation must be perfectly dry. For efficient operation, the feed should be

in a layer, one particle deep, which severely restricts the throughput.

Electrostatic separation is applicable to a limited size range, normally 20

mesh to 250 mesh. As complete separation is not likely to be obtained in a

single pass electrostatic separator, it is usual practice to re-pass separated

fractions through other separators as shown in Figure 3.

Figure 3 Multi-pass electrostatic

separator

Note: E - Discharge Electrodes

In Dielectric separation, ore consists of minerals

of various dielectric constants is suspended in a non-conducting fluid whose

dielectric constant is intermediate between that of two groups of minerals and

a converging electric field is set up within the suspension. Then the particles

having dielectric constant higher than the fluid travel in the direction of

most rapid increase in electric field and the particles having dielectric constant

lower than the fluid travel in the opposite direction. The dielectric

separation process is applicable to particles finer than 60-mesh and is used as

a research tool for study of minerals. It has no industrial application.

评论

发表评论