Beneficiation process of Manganese ore

Manganese is an important ferrous

metal. Manganese ore is mainly divided into two categories: manganese oxide and

manganese carbonate. Different mineral processing methods are often used

according to different ore properties.

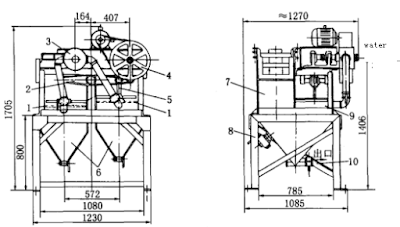

Figure1.gravity separation

1. Manganese oxide

This type of ore is mainly the secondary manganese oxide ore in the

weathered ore deposit, and the primary and secondary manganese oxide ores of

some sedimentary and hydrothermal deposits. Manganese minerals in ores are

mainly pyrolusite, pyrolusite and manganese ore. Gangue is mainly silicate

minerals and carbonate minerals, often accompanied by iron, phosphorus and

nickel and cobalt. The main beneficiation

method of manganese oxide ore is gravity. Weathering type oxidation manganese

ore often contains large amounts of mud and mineral powder, production of the

ore washing and gravity separation. The ore washing to remove slime, mine net

income, some can be used as a finished ore, some need to use the jig and shakingtable etc. Washing overflow sometimes needs to be further recovered by means of

gravity separation or strong magnetic separation. Some sedimentary type of

primary manganese oxide ore, due to the mining and dilution, the production of

heavy medium and jigging to remove the gangue, and get massive concentrate.

In the iron ore containing iron oxide, the iron minerals are mainly

limonite. Iron and manganese are difficult to be separated by gravity

separation, flotation or high intensity magnetic separation. The reduction

roasting and magnetic separation method is needed. The washing, reduction,

roasting, magnetic separation and gravity separation process is often used in

industry.

Figure2. 6Sshaking table

2. Manganese carbonate ore

The main manganese

minerals in sedimentary manganese carbonate ore are magnesite, calcite, sulphur

calcite and siderite. Gangue has silicate and carbonate minerals, and is also

associated with sulfur and iron impurities. The ore is generally more complex. The

granularity of manganese mineral is thin to a few microns, and it is difficult

to be dissociated. It is often difficult to get high grade of concentrate. The

production practice of manganese carbonate ore is less, and the methods of

strong magnetic separation, heavy medium ore dressing and flotation are

studied. Some sedimentary types of sulphur containing manganese carbonate ores

have been used in the industrial process of sequential preferential flotation

of carbonaceous shale, pyrite and manganese minerals. Some hydrothermal type

manganese carbonate ores containing lead and zinc carbonate have been used in

the flotation - strong magnetic separation process. Some sulfur rich ores,

manganese minerals mainly sulphur manganese ore, can be used to remove sulfur

by roasting. Some rich manganese carbonate ores are produced by roasting,

removing volatile components and getting the finished ore.

Figure3.Jig

Manganese oxide and

manganese carbonate ore contain some refractory ores. Manganese is closely

associated with iron, phosphorus or gangue. The particle size is very thin and

difficult to be sorted. It can be treated by smelting. For example, the method

of manganese rich slag treatment for high phosphorus, high iron and manganese

ore, the production of activated manganese dioxide by nitric acid leaching and

the production of metal manganese have been produced in industrial production.

sinonine can also provide sand washing plant epc.

评论

发表评论