Ore transportation

In

a mineral processing plant, operating at the rate of 400,000t/d , this is

equivalent to about 28tof solid per minute, requiting up to 75 m3 /min of

water. It is therefore important to operate with the minimum upward or

horizontal movement and with the maximum practicable pulp density in all of

those stages subsequent to the addition of water to the system. The basic

philosophy requires maximum use of gravity and continuous movement over the

shortest possible distances between processing units.

Dry

ore can be moved through chutes, provided they are of sufficient

slope to allow easy sliding, and sharp turns are avoided. Clean

solids slide easily on a 15-25° steel-faced slope, but for most

ores, a

45-55°working slope is used. The ore may be difficult to control

if the slope is too steep.

Thebelt conveyor is the most widely used method of handling loose bulk

materials. Belts now in use are with capacities up to 20,000t/h and single flight lengths exceeding

15,000m, with feasible speeds of up to 10 m/s.

The

standard rubber conveyor belt has a foundation of sufficient strength to

withstand the driving tension and loading strains. This

foundation, which may be of cotton, nylon, or steel cord, is bound

together with a rubber matrix and completely covered with a layer of

vulcanised rubber.

The

carrying capacity of the belt is increased by passing it over troughing

idlers. These are support rollers set normal to the travel of

the belt and inclined upward from the centre so as to raise the

edges and

give it a trough-like profile. There may be three or five in a set

and they will be rubbercoated under a loading point, so as to

reduce the wear and damage from impact. Spacing along the

belt is at

the maximum interval which avoids excessive sag. The return belt is

supported by horizontal straight idlers which overlap the

belt by a few inches at each side.

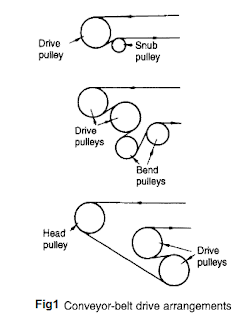

To

induce motion without slipping requires good contact between the belt

and drive pulley. This may not be possible with a single

180 ~ turn over a pulley and some form of "snubbed pulley"

drive or "tandem" drive arrangement may be more effective

(Figure 1).

The

belt system must incorporate some form of tensioning device to adjust the

belt for stretch and shrinkage and thus prevent undue sag between

idlers, and

slip at the drive pulley. In most mills, gravity-operated arrangements

are used which adjust the tension continuously (Figure 2).Hydraulics

have also been used extensively, and when more refined belt-tension control is

required, especially in starting and stopping long conveyors,

load-cell-controlled

electrical tensioning devices are used.

The

reliability of belt systems has been enhanced by advances in control

technology, making possible a high degree of fail-safe

automation. A series of belts should incorporate an

interlock system such that failure of any particular belt

will automatically stop preceding belts. Interlock with devices being

fed by the

belt is important for the same reasons. It should not be possible to

shut down any machine in the system without arresting the

feed to the machine at the same time and, similarly, motor failure should

lead to the

automatic tripping of all preceding belts and machines.

Sophisticated electrical, pneumatic and hydraulic circuits have been

widely employed to replace all but a few manual operations.

Several

methods can be used to minimise loading shock on the belt. A

typical arrangement is shown in Figure 3 where the fines are

screened on to the belt first and provide a cushion for the larger

pieces of rock.

Feed

chutes must be designed to deliver the bulk of the material to the centre

of the belt and

at

a velocity close to that of the belt. Ideally it should be the same, but

in practice this condition is seldom obtained, particularly

with wet sand or sticky materials. Where conditions will allow, the

angle of the

chute should be as great as possible, thereby allowing it to be gradually

placed at lesser angles to the belt until the correct speed of flow is

obtained.

The material, particularly if it is heavy, or lumpy, should never be

allowed to strike the belt vertically. Baffles in transfer

chutes, to guide material flow, are now often remotely controlled

by hydraulic

cylinders. The conveyor may discharge at the head pulley,

or the load

may be removed before the head pulley is reached. The most

satisfactory device for achieving this is a tripper. This is

an arrangement of pulleys by which the belt is raised and doubled

back so as

to give it a localised discharge point. It is usually mounted on

wheels, running on tracks, so that the load can be delivered at

several points, over a long bin or into several bins. The discharge chute

on the

tripper can deliver to one or both sides of the belt. The tripper may be

moved by hand, by head and tail ropes from a reversible

hoisting drum, or by a motor. It may be automatic, moving backwards

and forwards

under power from the belt drive.

Shuttle

belts are reversible self-contained conveyor units mounted on carriages,

which permit them to be moved lengthwise to discharge to either

side of the

feed point. The range of distribution is approximately twice the length of

the conveyor.

They

are often preferred to trippers for permanent storage systems because

they require less head room and, being without reverse

bends, are much easier on the belt.

sinonine can also provide sand washing plant epc.

评论

发表评论