Autogenous and Semi-Autogenous Mills

Disintegration and size reduction of some ores is

possible in tumbling mills without the aid of grinding media. Grinding mills in

which comminution takes place without grinding aids are known as Autogenous Grinding (AG) mills or Fully Autogenous Grinding mills

(FAG). These mills use large lumps of rock as the grinding media. Mills that

use intermediate size rock or pebbles as a grinding medium are also autogenous

mills but are known as pebble mills. Mills

that grind hard ores with fracture characteristics that do not lend themselves

to fully autogenous milling are charged with a small amount of steel balls to

assist in the size reduction. These are known as Semi-autogenous Grinding (SAG) mills, hi the mining industry all

of these types of mills are in use.

The disintegration and size reduction of ores in

AG/SAG mills is brought about by a combination of impact, attrition and

abrasion forces during mill rotation. Particles at the toe of the mill charge

receive the maximum impact forces from falling rocks and other grinding media.

Particles in the body of the mill charge partly slide from different heights

and are subjected to attrition and abrasion resulting in size reduction.

The operation of AG/SAG mills therefore involves

the use of cheaper grinding media as a replacement for expensive steel balls

and rods which greatly affect the wear on liners. They are therefore less

expensive to operate. It is necessary that the ore should provide a sufficient amount

of lumps that would last for a reasonable time to act as the grinding medium.

Such ores have been described as competent ores. Ores that break up easily are

referred to as either non-competent or incompetent ore.

Structure

of AG/SAG mill

Mills are designed with tapered conical ends

(Fig.1) or square ends (Fig.2). High aspect mills with conical ends are

sometime referred to as pancake mills

while mills with square ends are called square

mills. The diameters and lengths of square mills are nearly equal.

Most AG and SAG mills have slotted steel and rubber

liners and are fitted with lifter bars. The liners are either waved or grid

type. The grid liners are being increasingly used due to their longer life

brought about by ore and balls being trapped in the grids. The trapped ores and

balls build up a hard surface on the liners protecting them somewhat from wear.

The present tendency is to use composite liners with lifters at the feed end of

a mill to initiate impact crushing followed by wave liners along the rest of

the length of the mill. Several combinations are constantly being tried to

improve liner and shell life. The basic object of liner design is to promote

comminution by impact and attrition instead of abrasion.

The discharge ends are fitted with slotted grates

acting as a diaphragm, which holds back the larger particles from discharging

into the product stream. The size, spacing and design of the holes in the

diaphragm are important as they affect the rate of throughput and product size.

Open-ended discharge helps to solve problems arising out of high-speed mill

rotation in the region where the speed is in excess of 90% of the critical

speed. To improve the efficiency of diaphragms at high speeds of rotation,

curved lifters have been used. Three types of discharge ends are used, namely

mills with wide peripheral discharge, mills having a scoop after the grate to

lift the product and mills having the discharge through a trunnion.

Fig1. High aspect ratio AG/SAG mill with

grating and conical ends

Fig2. Square AG/SAG mill with grating

AG/SAG mill circuit

In a mineral processing plant designing a

crushing-grinding circuit, the concentration of the mineral in an ore and its down

stream treatment is of prime importance. Equally important is the liberation

size of the mineral, which determines the ultimate grind. The commonly used

circuits for AG/SAG mills are:

1. open circuit with a trommel or screen as the

classifier,

2. closed circuit with cyclone classifier,

3. open circuit with closed circuit ball mill, and

4.

open circuit followed by a secondary crusher and then ball milling.

The first two types may be called single stage

operation while the last two are two-stage operations. Most AG/SAG mills

operate in open circuit (Fig.3) when the product size is usually coarse.

Usually provision exists for installing a classifier like a straight screen, a trommel

or a curved DSM screen to remove critical sized pebbles (scats). For finer and

more uniform product, closed circuit grinding with classifiers, like a

hydrocyclone, is usually employed (Fig.4).

Fig3. SAG mill circuit in open circuit

Fig4. SAG mill in closed circuit

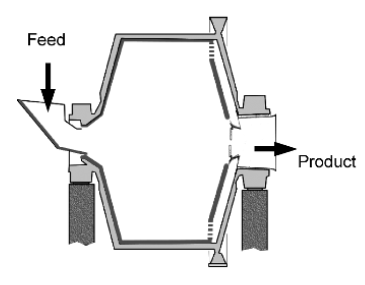

A two stage close circuit-grinding set-up with

hydrocyclone is shown inFig.5

Fig5. Two stage autogenous - ball mill

circuits

The main problem in designing and operating an

AG/SAG circuit is the tendency to build up the 25 -50 mm fraction of the charge

which hampers throughput. This specific size fraction that builds up in the

mill is referred to as the critical

size. Therefore pre-treatment of the feed should be such that the

presence of this fraction is minimal. If the build up of critical sized pebbles

is too great 50 - 90 mm slots are cut into the grate (pebble ports) to allow

the scats to discharge from the mill. These scats are crushed before returning

to the SAG mill or passing onto a ball mill in an ABC (Autogenous/Ball

mill/Crusher) circuit (Fig.6).

Instead of recycling the larger size fraction, the

oversize product from AG/SAG mills is sometimes prevented from discharging from

the mill by using a reverse spiral at the discharge end and washes back into

the mill for further grinding .

Fig6. SAG mill, HPGR and ball mill in an ABC

closed circuit

Low aspect mills are best suited to low to medium

competent ores while high aspect mills are more commonly used for competent

ores either as single stage circuits or autogenous-ball mill two stage

circuits. The larger diameter and short length provides better impact breakage for

the competent ore.

评论

发表评论