Thickener and its circuit

In beneficiation plant, thickeners are essentially clarifiers producing

a clearer over flow. The design considerations are based on the settling rates

of the slowest settling particles and conditions for minimum disturbance of the

medium (water) through which the solid particles are allowed to settle. To

achieve these objectives cylindrical tanks with conical or flat bottoms are

used and the velocity of the feed slurry entering the settling tank is

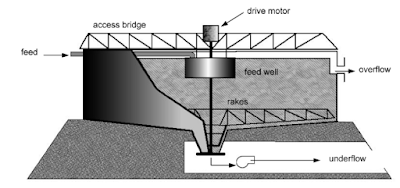

minimised to reduce turbulence in the settling tank. A schematic diagram of a

typical thickener is shown in Fig.1. The feed in the form of slurry is

generally guided by a launder, which is laid at a slope just sufficient for the

slurry to flow without depositing any solids. The feed launder terminates in a

feed well located at the centre of the tank. The feed well is designed to break

the fall of the slurry and dissipate the energy.

Fig1. Sketch of bridge type thickener

The feed well is concentric with the

rake driving shaft. The rakes are bolted or welded on to this drive shaft and

for long and large rakes they have additional support from cables. Usually four

rakes are employed of which two may be short and two long. Attached to the rakes

and below them are spikes, particularly in situations where the sludge is

thick. The spikes help to break up the sludge and render it more suitable for

pumping. The rakes are driven by a motor which is mounted on a plate above the

well. An alternative is to mount the drive motor on a track running along the

rim of the tank. A bridge usually runs from the

periphery to the centre of the tank. It

is supported by the wall of the feed well and the rim of the tank. The bridge

serves as a walkway and also carries an open launder (or pipe), which carries

the slurry to the feed well. In some designs the bridge spans the entire length

of the tank. As in clarifiers, the bottom of most tanks slope towards the

centre where the thickened underflow sludge accumulates. When a flat bottomed

tank is designed, the settled sludge builds up to form its own slope depending

on the angle of repose of the material thus forming an artificial sloping tank

bottom. The sludge collected at the bottom is discharged through an outlet

shaped like a cone with steep cone angle. Alternately, the thickened slurry is

swept towards a trench at the bottom of the tank. Usually a scraper is

installed for smooth delivery of sludge from the discharging cone or trough. A

slush or centrifugal pump subsequently removes the sludge. The thickener tanks

are usually fabricated using steel sheets. But tanks with concrete sides are

quite common. Some small tanks (usually < 30 m in diameter) are made of

plastics. The

whole assembly is installed either

above ground sitting on pillars or at ground level with the discharge well

below the ground level. In the latter case, an access tunnel is provided where the

discharging pump is located. In some installations the discharge pump is

located above the tank; in such cases, a suction pipe runs down the centre

column to the bottom well. Alternatively, a submerged motor pumps the under

flow slurry to the top of the tank discharging its contents to a holding tank. Several

variations are known to exist. For instance the rakes are either supported by

cross beams or truss above the tank or supported by the central column and

cables. The cables are also connected to torque meters. Fig.1 is a sketch of a bridge

thickener where the bridge runs across the thickener tank. The bridge

support the rakes and the motor rotating the rakes sit on a platform in the

centre of the tank. The rakes are bolted to the central column which is rotated

by the motor. The Bridge thickeners have a maximum diameter of about 30 meters.

When the rakes are supported entirely

by the central pillar, the access bridge usually runs

half way on the tank surface

terminating on the central pier. The centre pier thickeners are

considerably larger than the Bridge

type. The diameter of the tank ranges from about 35-180 meters.

A variation is the tray thickener where trays or

compartments are placed one on top of the

other. Each tray acts as a thickener

and the assembly operates in parallel with a common pier or shaft where the

rakes are fixed. Clarification takes place in series operation, that is, the thickener

underflow from the top compartment serves as feed to the lower compartment. Ultimately

the underflow from say, a six tray thickener, form the final thickened

underflow. Similarly all the overflow from each tray combine forming the final

overflow slurry. Fig.2 is a schematic diagram of a 3-compartment clarifier. Up

to seven compartments are available.

Fig2. Schematic diagram of a tray type

clarifier

The thickening process is accelerated

by the addition of flocculants Hi-Capacity

thickeners allow a mixing arrangement in the feed box where the

flocculant is intimately mixed. The other design features of the

Hi-Capacity thickeners are similar to the Bridge thickeners. While installing

the feed pipe or launder to thickeners, the slope is held at 1 to 1.5. this

slope provides minimum turbulence of the settling slurry in the tank.The feed

is actually made to enter about a meter below the surface of the tank level

thus helping to minimise turbulence. The feed well diameters are between

1 and 1.2 m with lengths of 1.2 to 5 m. Tank sizes vary according to

feed characteristics and the sedimentation time. Sinonine suggested that the water depth should be between 3.0 and

3.6 m and the feed well size about 25% of the basin area.

A recent innovation is the E-Cat

thickeners which has dispensed with the rakes and introduced clarifying cylinders through

which the suspension passes to produce the clear over flow (Fig.3). These

thickeners are designed for rapid sedimentation by the use of flocculants. The

clarified slurry then passes through filters producing a clear overflow.

Fig3.E-cat thickener

Thickener Design-Batch Process

Thickeners have been designed using the

basic laws of sedimentation. Empirical methods

devised by manufacturers are also used

for rapid work. For designing , the chief criterion is to determine the

relation between the settling velocity and the dimensions of the vessel to be used

for each particular slurry. The settling velocity for a particular slurry can

be easily determined in the laboratory by using small-scale tests. The tests consist

of determining the downward movement of the boundary of the clear liquid and

the suspension. It has been found that this rate is initially constant but the

rate decreased as the particles slowly settled to the bottom and the interface

met the sludge zone. This can easily be visualised from Fig. 4 where the

progressively increasing concentration with depth is shown. It is obvious that

the deeper the vessel and longer the time given for settling, the clearer will

be the supernatant liquid and the thicker will be the sludge.

The decrease in the settling rate is

due to hindrance by increased crowding of the particles as they settle and

collect at the bottom of the vessel. At the sludge-forming layer, the particles

pack down by displacing the liquid in between. In so doing, the clear liquid

level rises. These considerations apply both to batch and continuous processes,

with the difference that in the continuous process a balance between the flow

rate of the overflow stream and the removal rate of the sludge has to be

maintained.

Fig. 4 Sedimentation in a thickener

Operation of thickeners

The operation of thickeners involves a

delicate balance of the feed rate, the overflow rate and the underflow

withdrawal rate and is dependant on the concentration of the feed, overflow and

underflow streams The feed stream generally enters the feed well at a speed of

about 15 m/min but this would depend on its characteristics, such as

concentration (liquid/solid ratio), particle size, particle shape and

viscosity. The characteristics of the overflow and underflow streams depend on

the sedimentation time and particle properties like, specific gravity, shape ,

size and wettability. If the particles are very small, the associated surface

charge or zeta-potential is of importance.

Flocculants play an important role in

affecting the surface charge on particles and help to

accelerate or reduce the rate of sedimentation by dispersion or

agglomeration.

Rakes help to increase the

sedimentation rate and also break up large agglomerates. The

rakes are operated between 8-18 m/min.

To prevent damage to the rakes and torque meters the recommended operation is

to discharge the sludge at regular intervals at predetermined set conditions.

It is necessary for the operator to detect the build up on the rakes and

operate to avoid the jamming and seizure of the rakes. Usually the built-up mud

tends to form islands which grows and develops a moment that could easily

damage the rake mechanism. During normal operation the rise rate varies from

about 0.01—0.03 m /min/m of cross-sectional area and the detention time is

between 2-5 hours.

Thickeners in Circuits

In minerlprocessing plant ,Thickeners used to produce low solid overflows (eg. about

1% solids), may be referred to as clarifiers. Both thickeners and clarifiers

are extensively used in metallurgical operations for dewatering purposes. In

processing gold, nickel, iron, copper ores etc. thickeners are used to produce

overflows suitable for use as process water in circuits such as flotation. The

clear overflow water is used for re-pulping the flue dusts or fine dust from

precipitators. Therefore the feed to thickeners vary considerably. A common

arrangement is illustrated in Fig.5

Fig5. Thickener arrangement

Thickeners serve as classifiers when a

near clear overflow is required. For example

clarifiers used in iron blast furnace

dust cleaning plant or electrostatic precipitator circuits are required to

produce clean overflows as the water is for reuse and the sludge is for

secondary use. In such cases the sludge is washed continuously by counter

current decantation., where the underflow from a thickener/clarifier is pumped

to the next thickener/clarifier (connected in series) forming the feed to the

second tank. A typical set up is illustrated in Fig. 6 consisting of three

units of thickeners/clarifiers.

Fig6. Thickeners in a counter-current

decantation arrangement

Such setups are structured so that the

overflow from one clarifier/ thickener flows by gravity to the adjacent

clarifier. The sludge is usually pumped to the next clarifier. Make up water is

added at the third thickener.

sinonine can also provide sand washing plant epc.

Sinonine technology team

评论

发表评论