PERMANENT MAGNETS

In beneficiation plant, Most of

the weakly magnetic minerals, such as garnet, ilmenite, and magnetic impurities in silica sand, can be effectively separated with a magnetic separator

that has a flux density greater than 6,000 gauss. For nearly a century,

induced-roll magnetic separators were the only economically viable unit

operation in these applications. In spite of their considerable success,

induced-roll separators have certain limitations in their selectivity and

application. The development of permanent-magnet technology during the last two

decades has reestablished the importance of magnetic separation and has

increased the efficiency of fine-particle separations that were not successful

with induced-roll magnets.

Principle and Design

In the last decade, magnetic separation technology has undergone a

revolution. Research in material science and ceramic technology has culminated

in the development of new permanent rare-earth magnets and superconducting

alloys that can be used to build high-gradient magnetic separators.

Successful adaptation of these new magnetic materials combined with the

knowledge of magnet geometry has led to the design and development of a number

of new magnetic separators. These separators have opened niche markets that

were previously considered beyond the realm of magnetic separation. These new

separators are capable of

_ Effectively removing magnetic impurities or reducing their concentration

(even to ppm levels)

_ Producing high-grade mineral separates

_ Operating on virtually no energy, which makes them economical

_ Generating higher magnetic flux levels up to 21,000 gauss or 2.1 tesla

Recent improvements in magnet composition and design have led to the

development of permanent magnetic separators. These improved rare-earth

permanent magnets (e.g., NdFeB magnets) have a magnetic attractive force an

order of magnitude greater than that of conventional permanent magnetic circuits.

The two main types of dry permanent magnetic separators that have found wide

industrial applications are the rare-earth drum (RED) and the rare-earth roll

(RER). They are widely used to separate weakly magnetic materials, such as

garnet, ilmenite, and chromite, and also to separate magnetic impurities present

in low concentrations in silica sand.

Rare-earth

Drum Separator.

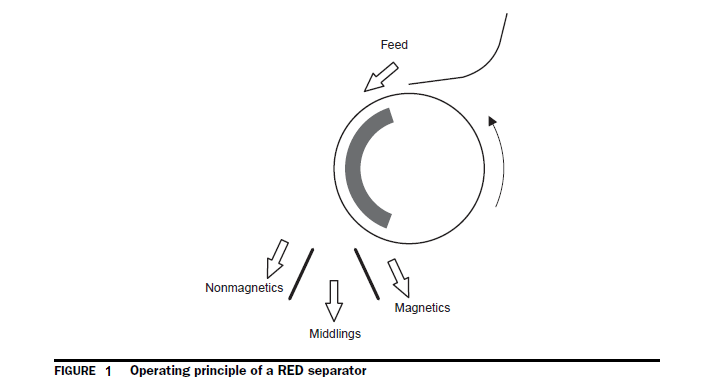

In an RED separator, the NdFeB magnets are uniquely arranged to provide an

intense (up to 9,000 gauss) and “deep” magnetic field perpendicular to the drum

surface (Figure 1). Once the particles are on the drum surface, they experience

uniform flux density that minimizes the misplacement of pinned particles to the

middlings. The weakly magnetic particles pinned to the drum are carried to the

region of no magnetic intensity and are released as magnetics. The centrifugal

force of the rotating drum throws those particles not influenced by the

magnetic field into the nonmagnetic hopper.

An industrial-scale RED separator usually has three drums (Figure 2). In

general, the top drum is a low-intensity (up to 2,000 gauss) scalper magnet to

remove ferromagnetic particles, and the nonmagnetic fraction is subsequently

treated on the REDs. The main purpose of the scalper is to protect the bottom

two REDs, as well as to increase their capacity. Some separators have a

built-in internal aircooling system to protect the magnets from overheating

when the feedstock is preheated, as in plants that process beach and silica

sand.

Rare-earth

Roll Separator.

The feed is fed onto a thin belt (usually 7.6 × 10–3 to 5.1 × 10–2 cm) that travels at a very high

velocity. The unique aspect of these separators is the way in which the magnetic separator is configured as a

head pulley. The feed material is passed through the magnetic field, and the

magnetic (or weakly magnetic) particles are attached to the roll and separated

from the nonmagnetic stream (Figure 3).

Drum separators can effectively handle coarse particles (12.5–0.075

mm), whereas roll separators are very effective in treating fine particles

(<1 mm). The capacity of the deeper-field drum separators is generally

higher than that of the roll separators at 400–500 lb/h/in. for drum separators but 100–300

lb/h/in. for roll separators. The major advantage of the drum separator is its

low maintenance cost, because it does not contain a belt that must be replaced

frequently. However, both separators have their own niche markets. Drum

separators can treat coarser particles, such as garnet, ilmenite, and iron ore,

at a higher throughput. Roll separators can be used in producing high-grade, high-purity

glass sand products when the feed material is not preheated.

Eddy

Current Separator.

In the case of the RED and RER magnetic separators, the outer drum or the

belt rotates, while inside the shell, rare-earth magnets are mounted on a

stator. However, in an eddy current separator not only does the nonmetallic

outer drum rotate but also the inside shell, which is a faster-moving rotor

containing rare-earth magnets arranged in alternating polarity to produce

induced eddy currents. The induced eddy current sets up a repulsive force in

good conductors and thus separates nonferrous electrically conductive metals,

such as copper and aluminum, from nonconducting materials.

Wet Permanent Magnetic Separator

A wet permanent magnetic separator is shown in Figure 4.

The permanent-magnet (NdFeB) bars are positioned more or less horizontally

inside a revolving drum made of stainless steel. This separator provides a

field strength of 0.7 tesla on the drum surface. The pulp tank is made of stainless

steel with concurrent or semicountercurrent flow tank design and an adjustable

discharge gap at the magnetics discharge end. The separator is equipped with an

adjustable valve on the nonmagnetics discharge pipe. This valve helps to

control the flow rate and overflow level. It has found industrial applications

in processing low-grade (martitic) iron ore.

评论

发表评论