Flotation system

In beneficiation plant, Flotation, like all other separation

processes, is imperfect in that simply by applying this process only once, very

little separation may be achieved. For example, the underflow from a flotation machine unit may have many

hydrophobic particles that have failed to encounter an air bubble, or the

overflow may have hydrophilic particles that have simply been caught in the wake

of an air bubble or in a collection of hydrophobic particles secured to a

bubble. It is, therefore, common practice to operate many cells in complicated

series – parallel arrangements, perhaps with adjustment of chemistry at some

point. This is necessary because only a limited separation is usually

attainable in a single device, and as such there is a need for roughing,

cleaning, and scavenging components in a circuit.

Generally

speaking, roughing is the primary operation, which utilizes a moderate

separating force to remove the fully liberated valuables. Scavenging utilizes

strong chemistry conditions to recover as much of the remaining valuables as

possible. Finally, cleaning utilizes a low separating force which upgrades the

rougher concentrate by removing misplaced waste material.

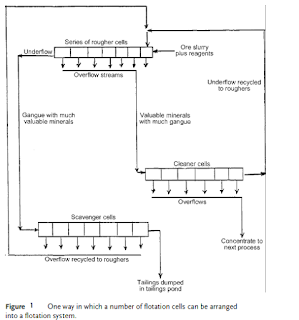

A simple

arrangement of using these elements is shown in Figure 1. A series of rougher

cells (with the underflow passing from one cell to the next) makes a rough

separation of the slurry obtained after grinding(ball mill) into two streams. The mineral-rich stream then passes to

a second series of cleaner cells whose objective is to remove as much residual

gangue as possible, and yields a slurry of concentrate particles or heads that

has much of the valuable mineral in the ore, and a second stream that is

recycled to the rougher cells. The other stream from the rougher cells, having

less of the valuable mineral (but not so minor as to be discarded), goes on to

the scavenger cells where as much as possible of the valuable mineral is

recovered from the tailings stream departing to the waste pond. This scavenged

valuable mineral is put back to the rougher cells.

评论

发表评论