Ore washining and water treatment

In mineralprocessing, Washing, mainly used in the enrichment process of

industrial minerals, coal,aggregates, sand and gravel, normally with the

products in solid form. (size = 1 mm and coarser).

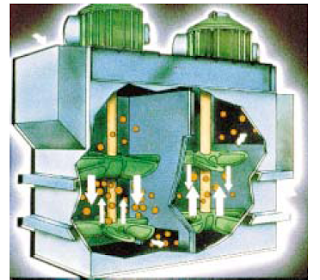

Single or double

shaft log washers are used for washing of gravel. Contaminated material is fed

at the trough bottom and is transported upwards by blades in abscrew pattern

due to friction between the material. Effluent in slurry form leaves via an

overflow weir.

Wet screens

Water spraying

can be used to wash materials on a screen regardless of hole size in the

screening media. If the hole size is 20 mm or less, water spraying increases the

capacity (inversely proportional to the hole size).

Aquamator separator

The Aquamator is

developed for efficient washing of waste material of lower densities like coal,

wood etc. Used mainly for gravel, chippings and demolition rubble. The water

and feed form a bed with a density high enough ( SG range1.2-1.6) enabling

light material to float off.

Typical feed

size is plus 2 mm up to 32 mm. (9 mesh – 1.3”)

Tumbling scrubber

If solids of

rock, gravel or minerals contain a high and sticky content of clay and dirt that has to

be removed, wet screening is normally not effective enough. A medium speed

washing drum for scrubbing solids against solids is then the option. The drum is

relatively short in relation to its diameter. Water requirements per ton is the same as

for wet screening.

These scrubbers

are mainly used for washing of material below 10 mm in size. Very high energy

inputs are possibly used for washing of silica sand for glass making and

cleaning of foundry sand. The machine is also suitable for clay blunging and

lime slacking,

Wash Water Treatment

All washing

operations are normally consuming a lot of expensive water. Not only costly,

but also containing a lot of washing effluents both coarse and fine. Water and

effluents that have to be processed partly to recover some value (coarse material

and water), partly to protect the environment from damage (sludge fractions). Most washing operations today must have systems for this treatment.

Wash water treatment stages

Depending on

local conditions and restrictions, one, two or three treatment stages may be required,

see below.

Wash water treatment – closed system

After recovery

of coarser material the fines can be treated in a closed system recovering all

process water and bringing the fine solids into a transportable form.

For more

information, please contact sinonine

评论

发表评论