Mechanical Dewatering

Mechanical

dewatering means mechanical removal of liquids from a slurry to

obtain the

solids in a suitable form and/or recovery of a valueable liquid for:

•

Further processing

•

Transportation

•

Agglomeration

•

Disposal

•

Recovery of valuable liquids

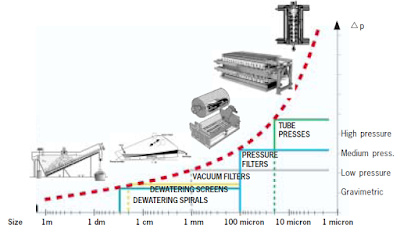

Gravimetric Dewatering

When the

particles in a slurry are too coarse for the capillary forces to “trap” the water,

the use of gravity is enough to remove the water and give at least

transportable solids.

Spiral Dewaterer

Spiral dewaterer

for coarse solids (not deslimed).

•

Feed 1% solids by w.

• 10 – 1 000 m3/h (44-44 000 USGPM)

•

Remaining moisture approx. 30% h2O

•

Large sedimentation-pool

• Oil

scimmer as option

Sand spiral classifier(sand screw)

This is a

simpler version of the Spiral dewaterer mainly used for natural sand. These

sands are normally classified (particles below 10-50 micron are removed) meaning

that the sedimentation pool is very limited compared to the Spiral Dewaterer.

•

Feed ratio sand : water app. 1:3

•

Capacity 6-95 m3/h

•

Remaining moisture content

20-25 % H2O by weight

•

Screw inclination app. 25 degree.

This is a

version of a screen in linear motion moving the solids upwards on an inclined

plane at an inclination of 5o. Dewatering takes place in the moving sand bed.

•

Only for sand, coal or other deslimed solids

•

Feed containing max. 50 % solids by weight

•

Remaining moisture content 13-17 % H2O by weight

•

Capacities 70-190 (sand), 5-55 (coal)

Dewatering Wheel

The dewatering

wheel is mainly used in dredging of natural sand and gravel. The machine has a

simple water draining arrangement at the sand removal buckets. Therefore the

water content can be reduced down to 15-18 % H2O by

weight even if the feed contains certain fines. The pool is limited meaning

that the machine is sensitive to high volume flows.

• Feed

size (typical) 0-2 mm

•

Variable speed as option

•

Feed flow 1 500-2 400 m3/h

评论

发表评论