upgrading and thickeners

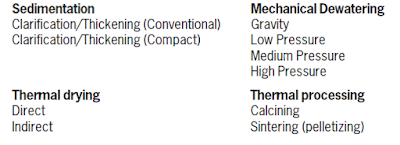

In mineralprocessing plant, With upgrading we understand, the further processing of the

final products from the enrichment stages in a process.

This is valid

both concerning the valuable minerals (the concentrate) and the waste minerals

(the tailings).

In the first

case upgrading means improving the product value by bringing the concentrate to

transportability or into a completely dry form. Processing can also go further

to calcining and sintering. On the tailing side upgrading means that waste

material (wash water, process effluents etc.) is properly taken care of in

order to protect the environment, to recover process water and to turn certain

portions into valueables.

Sedimentation

Sedimentation is

a continuous solid-liquid separation process with settling of solids by

gravity. Clarification is the process for removal of solids from a

dilute solid/liquid suspension. Thickening is the process

for concentrating particles in a supension by gravity compression

Flocculation

All

sedimentation technologies are related to particle size. One way of improving the

settling speed generally is therefore to increase the size of the particles.

Fine particles

can be connected together by coagulation or flocculation. The settling rate of

the combined particles will be higher than that of each individual particle.

Flocculation System

A handling

system is needed for flocculant utilisation. This comprises provision to mix,

store and dilute the polymer. The dilute polymer is then mixed with the feed slurry

and allowed to condition (or age) before a sedimentation or dewatering process.

.

Conventional Clarifier

Clarification is achieved when the liquid “upstream” velocity VL is lower than the sedimentation velocity of the solids VS.

Conventional Thickener

Continuous

thickening to give the required solids concentration in the underflow depends

on balancing the volumetric solids flow rate at a critical concentration with

the diameter of the thickener.

Bridge type thickener

For smaller thickeners,

up to 30 – 40

m diameter, the rakes and drive mechanism are supported on a bridge

superstructure, which straddles the tank as shown.

Centre Pier type thickener

For tanks over

30 – 40

m diameter a bridge structure will be imractical. The mechanism and rakes are

therefore supported from a centre pier and the bridge is only used for access

and to support feed pipe and launder.

Thickeners Drive mechanism

For bridge and

centre pier mounting. Options with and without automatic rake lifting system.

Automatic torque

monitoring Slewing ring bearing to accommodate out of balance loads on rakes Worm

and wheel and multistage epicyclic gearbox drive.

Control of thickeners

Torque is

electronically detected and monitored. Increased torque is a sign that the

solids loading in the thickener may be building up. This could indicate a process

problem (change in feed, blocked underflow etc.). In all these cases rakes and

drive have to be protected.

评论

发表评论