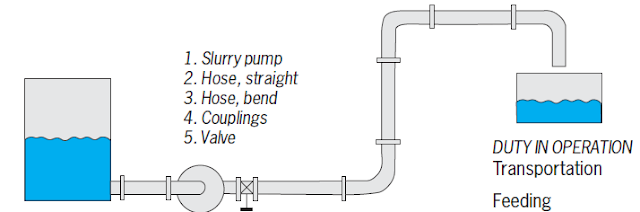

The Slurry Line

Slurry pumps are

important being the energy source in all hydraulic systems for slurry handling.

However, the slurry pumps are mainly just energy converters in the systems

(converting electric energy to hydraulic flows). Equally important is to design

“the slurry line” with the correct sizing of hoses (or pipes) including

• Hose lay-out

geometry (vertical and horizontal) needed for the transportation job

• Hose material

giving resistance to the wear and to the chemical environment

• Hose diameter

enabling maximum efficiency of the slurry system

SLURRY

OPERATIONS

Classification

Separation

Sedimentation

Mechanical

dewatering

Hoses are for

slurry handling what conveyor belts are for dry materials handling. Simple

products –

which just have to maintain their functions. Otherwise the process flow will be

interrupted and the up-time is gone.

There is just

one rule for lay-outs of slurry hoses and pipes, but a golden one.

“ Never use sharp bends when connecting them hydraulically! ”

• Every

slurry handling system needs proper hosing.

•

Carrying velocity in the hose must exceed the settling velocity.

• Too

high carrying velocity means increased power and wear.

• To

balance the optimum slurry speed with the correct hose diameter is important.

评论

发表评论