Thermal processing

In mineralprocessing plant, Dewatering by using Tube Presses represents the highest

energy level of mechanical upgrading of minerals. If further upgrading is

required we have to use thermal processing. Thermal processing is normally classified

according to operating temperature.

Thermal low ( 100-200° C)

Used for drying

- evaporating of liquids from solids - drying

Type of

equipment

•

Direct Heat Rotary Dryers

•

Indirect Heat Rotary Dryers

•

Steam Tube Dryers

•

Indirect Heat Screw Dryers (Holo-FliteR)

•

Fluid Bed Dryers

Thermal medium (850 -950°C)

Used for

calcining, clay swelling, limestone burning and foundry sand burn out

Type of

equipment

•

Direct Heat Rotary kilns

•

Indirect Heat Rotary kilns

•

Vertical Kilns

•

Fluid bed Kilns

Thermal high (1300-1400°C)

Used for

pelletizing of iron ore concentrates and petroleum coke calcining

Type of

equipment

•

Direct heat rotary kiln

Thermal processing basics

Thermal

processing is expensive. This means that lowest input in calories/ton is the

key issue. With raising operating temperatures this issue is getting more and more

critical.

Dryers are

normally not insulated but the kilns are refractory lined to protect the mechanical

parts from the high temperatures needed for processing. Also the systems for

heat recovery are getting more and more advanced with higher energy input.

Thermal

processing equipment is always supplied as an integrated system consisting of:

•

Mechanical Dryer or Kiln

•

Feed and product handling equipment

•

Combustion system (burner, fans, fuel system, etc.)

• Off

gas handling equipment

• Dust collection system (wet or dry)

•

Cooling system (optional)

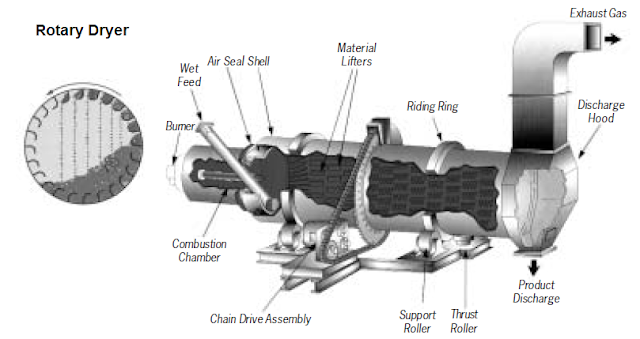

Direct Heat Rotary Dryer

•

Work horse of the mineral industry

•

Wide range of internal designs for effective drying from start to end

•

Special seals for closely controlled atmosphere

•

Effective combustion and low maintenance burners, safe and reliable

•

Diameter <0,6-5 m (2-17 ft), length 5-30 m (7-100 ft). Feed rates from less

than 1 ton to 500 tons per hour

•

Applications in minerals, clay, sand,aggregates, heavy chemicals and

fertilizers.

Indirect Heat Rotary Dryer (rotary Kiln)

•

Controlled environment interior excludes products of combustion

•

Heat transfer by conduction and radiation

•

Pulse-fired burners available

•

Facilitates recovery of off-gases and product vapours

•

Diameter 0,5m - 4,5 m (1.5-14 ft). Length 2.5 m to 30 m (8-96 ft).

•

Applications in hazardous-, ultra fine- and combustible materials. Regenera

tion of active carbon, pyrolysis of waste rubber (car types)

Iron Ore Pelletizing system (Grate – Kiln)

Lime Calcining System

Coke Calcining System

评论

发表评论